Eastern Highway Company is among the best road marking machine manufactures in Pakistan. Offering high quality, durable machines at best prices!

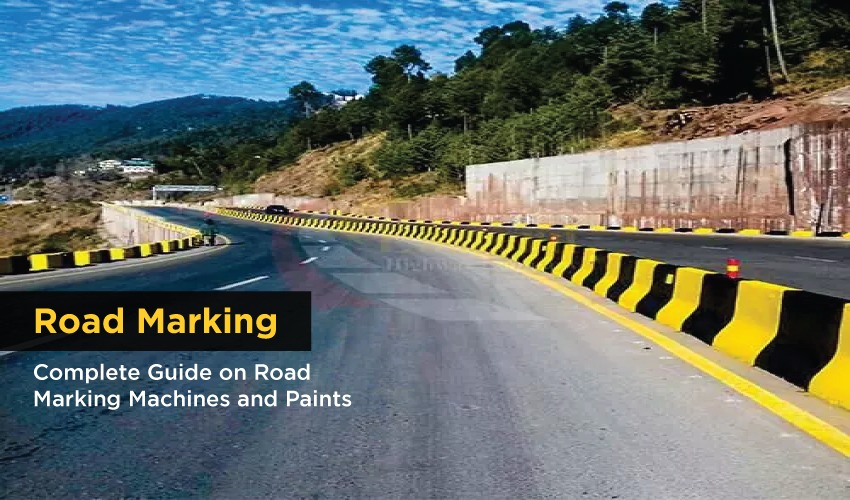

Making roads safe and easy to understand is really important. Everyone of us see lines on roads and often wonder whether is it done through road marking machines or manually. But, using paint to draw lines on roads can be slow and not very accurate. This can cause confusion and also pose danger for drivers and pedestrians.

This is where road marking machines are used for this purpose. These machines use smart technology to draw clear and long-lasting lines on roads. They make the roads look organised and help everyone while driving or walking.

Wondering to know what is road marking machine and how does it work?

In this blog post, we will explore road marking machines. We will learn about their different types, how they work, and why they are so helpful. Whether you are interested in how things work, or you just want to know how roads become safer, you will find interesting and easy-to-understand information here. So that you can decide for the best Road Marking machines manufacturers in Pakistan!

Join us to discover how these machines make our roads better, and how they play a big role in keeping drivers and pedestrians safe on the roads.

What is a Road Marking Machine

A road marking machine is a specialized device or vehicle designed to create various traffic lines, marking, lines, symbols, or road-related designs on asphalt or concrete surfaces. The process of line marking involves the application of thermoplastic paints or cold solvent paints onto the pavement surface. This is achieved through techniques such as screeding, extruding, and spraying.

These lines serve to provide guidance and information to both drivers and pedestrians. Moreover, they also indicate regulations related to parking, and stopping ad also prove helpful in other purposes such as:

- Guiding traffic

- Indicating lanes

- Conveying important information to drivers

- Improving road safety

Types of Road Marking Machinery

Composed road marking machine manufactures offer different types of machinery! Diverse road marking apparatuses are at one’s disposal, each endowed with distinctive attributes and functionalities. A few of the most prevalent categories comprise:

- Self-Propelled Thermoplastic Road Marking Machines

These machines are used to apply thermoplastic markings on roads. They have a heated tank that melts the thermoplastic material and a dispensing system to apply it on the road surface. They are equipped with guidance systems to ensure accurate and consistent markings.

- Hand-Pushed Thermoplastic Road Marking Machines

Similar to self-propelled machines, these are smaller and manually operated. They are used for smaller road marking projects and areas where access is limited for larger machines.

- Cold Paint Road Marking Machines

These machines are used to apply cold paint markings on roads. Cold paint markings are less durable than thermoplastic markings and are used for temporary markings or in areas with lower traffic.

- Two-Component Road Marking Machines

These machines are used to apply two-component materials. This is mainly used for high-performance road markings. The two components are mixed right before application to ensure optimal performance.

- Road Marking Trucks

These are large vehicles equipped with road marking equipment, including paint tanks, spraying systems, and guidance technology. They are used for larger road marking projects on highways and other extensive road networks.

- Airless Striping Machines

These machines use airless spraying technology to apply paint at high pressure. They are often used for line striping in parking lots, warehouses, and other areas where precise and durable markings are needed.

- Reflective Marking Applicators

These machines are used to apply reflective materials, such as glass beads or reflective paint. This is used to enhance the visibility of road markings at night or in low-light conditions.

- Pavement Marking Removers

While not exactly road marking machines, these devices are used to remove old or unwanted road markings. They use mechanical methods, such as grinding or blasting, to strip away existing markings.

- Hand-Pushed Machines

More compact and portable compared to their operator-driven counterparts, manual push machines find utility in smaller tasks like delineating pedestrian crosswalks and delineating parking spaces.

All these machines are engineered to be operated by a human with the capability to generate an array of markings encompassing solid lines, dashed lines, and various symbols.

How Does a Road Marking Machine Work?

The exact working process can vary based on the type of machine and the specific markings being applied, but here’s a general overview of how a road marking machine typically works:

First of all, the paint into the thermal insulation bucket to initiate the melting process. Once the paint is in liquid form, it is transferred to the marking hopper, ensuring a continuous flow.

Before starting the road marking process, the road surface needs to be cleaned and prepared. Any debris, dirt, and old markings are removed to ensure a smooth application.

When ready to commence line marking, position the marking hopper above the road surface with a specific gap. As the marking machine advances steadily, a well-defined line will be automatically drawn. Additionally, the glass bead spreader will evenly apply reflective glass beads onto the marked line.

In terms of a thermoplastic machine, the initial step involves heating and blending the paint in the thermoplastic pre-heater. Subsequently, the paint should be placed into the paint tank of the thermoplastic device. This machine can then be operated to create line markings: The paint is dispensed from the paint tank, passes through the marking shoes, and finally lands on the road surface.

When using a cold paint type machine, there is no requirement to heat or pre-mix the paint. All that’s necessary is to pour the paint into the machine’s paint tank. From there, the machine can be operated to create markings on the road. The paint is drawn from the tank, passes over the marking shoes, and is finally deposited onto the road surface.

Different Types of Markings

Road markings exhibit various forms based on their intended use and the surface they are being implemented on. Thus different types of machines are produced by road marking machine manufactures. Several typical kinds of markings encompass:

- Lane Markings: These markings delineate the lanes on the road and facilitate the orderly movement of traffic.

- Boundary Markings: Boundary markings are employed to demarcate the road’s periphery, furnishing drivers with navigation cues.

- Symbols and Signs: Symbols and signs furnish drivers with essential information, encompassing speed limits, areas where parking is prohibited, and locations of pedestrian crossings.

Factors Affecting Road Markings

Numerous elements can impact the excellence and resilience of road markings. These factors encompass the nature of the surface being marked, the chosen materials, and the prevailing weather conditions at the time of application.

Importance of Choosing the Right Road Marking Machine

Selecting the appropriate road marking machine holds immense significance in road construction endeavors. Employing an unsuitable machine can result in subpar markings, extended project schedules, and escalated expenses. On the contrary, opting for the correct machine can enhance productivity, curtail costs, and guarantee the longevity and exceptional visibility of the markings.

Things to Consider When Selecting Road Marking Machine

Here are some important things to consider while choosing a road painting machine:

Capacity for Workload

Workload capacity, in the context of a road marking machine, denotes its ability to manage a specific volume of tasks within a given time frame. This element holds significant importance due to its potential impact on project efficiency.

When dealing with sizeable projects featuring stringent deadlines, opting for equipment possessing a substantial workload capacity becomes essential to achieve swift and effective task completion. Conversely, for projects of a smaller scale and extended timelines, a machine with a lower workload capacity could be more suitable.

Nature of Tasks

Another pivotal aspect to contemplate is the nature of the tasks that the road marking machine will undertake. Distinct machine models cater to various kinds of tasks, such as creating lines, symbols, or surface markings.

To ensure optimal outcomes, it is imperative to select a machine explicitly designed for the specific task you intend to perform.

Efficiency

Efficiency stands as yet another critical consideration when deciding on a road marking machine. The machine should possess the capability to generate precise and distinct markings swiftly and accurately. Seek out a machine equipped with features such as customisation line widths, adjustable paint flow, and rapid-drying paint to enhance overall operational efficiency.

Sturdiness and Longevity

The durability of the road marking machine holds substantial sway, influencing both the machine’s lifespan and the quality of the markings it produces. Prioritize equipment fashioned from premium materials and robust construction methods to ensure longevity.

Machines engineered to withstand adverse weather conditions and intensive usage are more likely to endure over time and necessitate less frequent maintenance.

Simplicity of Operation

The road marking machine should offer effortless operability, even for individuals with limited experience. Seek a machine equipped with intuitive controls and explicit usage instructions.

Opting for a unit featuring automatic paint mixing and easily replaceable spray nozzles can greatly enhance operational ease and efficiency.

Adaptability

Adaptability stands as another critical aspect to contemplate when selecting a road marking machine. Prioritise a unit capable of serving a wide array of applications, encompassing road markings, parking lots, and sports fields. This choice can result in cost and space savings by eliminating the necessity for multiple machines.

Maintenance and Assistance

Factor in the maintenance and support prerequisites of the road marking equipment. Target equipment that boasts straightforward maintenance procedures, accompanied by a warranty and customer support. This guarantees swift resolution of any issues, minimising downtime and associated expenses.

Furthermore, safety considerations should not be overlooked during usage. Operators must don personal protective equipment (PPE), adhere to safety protocols, ensure proper ventilation, and undertake fire prevention measures to safeguard both themselves and others.

The Essential Components of a Road Marking Machine

Now let us discuss the essential components of road marking machine:

Marking Width Considerations

The width of road markings holds significant importance as it dictates the dimensions of lines and symbols formed. Distinct road marking machines offer varying marking widths, spanning from 5cm to more than 50cm. The marking width hinges on factors such as the spray gun’s dimensions and the spacing between nozzles. Opting for a road marking machine with a suitable marking width tailored to the specific application holds the utmost significance.

Variety of Paint

A pivotal component accompanying road marking machines is the paint variant utilised. The choice of paint hinges on the particular application and the nature of the surface to be marked. Varieties of paint, including thermoplastic, cold plastic, and water-based alternatives, are commonly employed.

Each type of paint possesses unique attributes encompassing endurance, reflectiveness, and application ease. Selecting a machine that aligns with the chosen paint type is critical.

Indispensable Handheld Spray Guns

Handheld spray guns play an essential role within road marking machines, empowering operators to craft precise markings even within challenging-to-access spaces. Lightweight and user-friendly, these guns predominantly serve in producing intricate symbols, arrows, and other detailed markings. Their utility extends to marking parking areas, pedestrian crossings, and bicycle lanes.

Sustaining Efficiency via Cleaning Systems

Integral to road marking machines, cleaning systems contribute profoundly to upholding the machine’s operational quality and efficiency. Typically encompassing a water reservoir, a pump, and a spray gun, the cleaning system works in tandem. The reservoir stores water that subsequently courses through the machine, cleansing nozzles and other components. This mechanism significantly mitigates blockages and ensures peak machine performance.

Enhancing Visibility with Glass Bead Systems

The incorporation of a glass bead system imparts reflective properties to the markings. These glass beads are typically combined with the paint and subsequently applied to the designated surface. Upon illumination from vehicle headlights, the glass beads refract light back towards the driver, heightening visibility and consequently, safety. This system proves particularly advantageous for marking roads, highways, and other settings prioritizing visibility.

Ensuring Safety While Operating a Road Marking Machine

Utilizing a road marking machine carries inherent risks, necessitating the implementation of stringent safety measures to safeguard both operators and fellow workers.

- Personal Protective Equipment (PPE): Operators must don appropriate personal protective equipment, including goggles, gloves, and masks. These items serve as a barrier against the potentially harmful fumes and chemicals associated with road marking tasks.

- Adherence to Safety Protocols: Operators are required to adhere to established safety protocols when operating the machine. A comprehensive understanding of the machine’s potential hazards and diligent observance of safety procedures are paramount.

- Optimal Ventilation: Given that road marking machines release noxious fumes, it is vital to ensure optimal ventilation within the work environment. This measure prevents exposure to hazardous chemicals and sustains a safe atmosphere for all personnel involved.

- Prevention of Fire Hazards: Road marking machines utilize inflammable materials like paint and solvents, posing a fire risk. Operators must exercise caution by securely storing such materials in designated areas and having readily accessible fire extinguishing equipment on hand.

To conclude, in the intricate world of road infrastructure, road marking machines play a vital role in ensuring safety, clarity, and order for both drivers and pedestrians. These intelligent devices replace the laborious and often inaccurate process of manual road painting. They are bound in delivering clear, durable, and organized markings that guide traffic, indicate lanes, convey crucial information, and ultimately enhance road safety.

The best Road Marking Machine Manufacturers in Pakistan!

Eastern Highway Company is one of the trusted and reliable road marking machine manufactures in Pakistan. Offering as many as 6 types of Road marking machines! All of these machines have been tested to provide high-end results and are equipped with latest technology to reduce paint wastage and improve paint coverage.

Feel free to contact our consultants to talk about the road marking machines that best suits your project!