Importance of Thermoplastic Road Marking Paint

The most significant contribution to enhancing road safety has been acknowledged as being route marking. Normal road marking paint quickly fades away, especially in high temperatures. Still, our Roadex Thermoplastic Road Marking Paint complies with all applicable international regulations.

This provides outstanding nighttime visibility, upholds traffic laws, and gives drivers the information they need. Thermoplastic road marking Paint or (TP paint) is a premium road marking product that offers exceptional adherence and a thicker film for long-lasting performance.

We take pride in that every staff member is qualified and provides a high caliber of service. Our team only uses the best materials. We stay current with new technology for removing lines from roads and road markings.

Specifications of Thermoplastic Road Paints

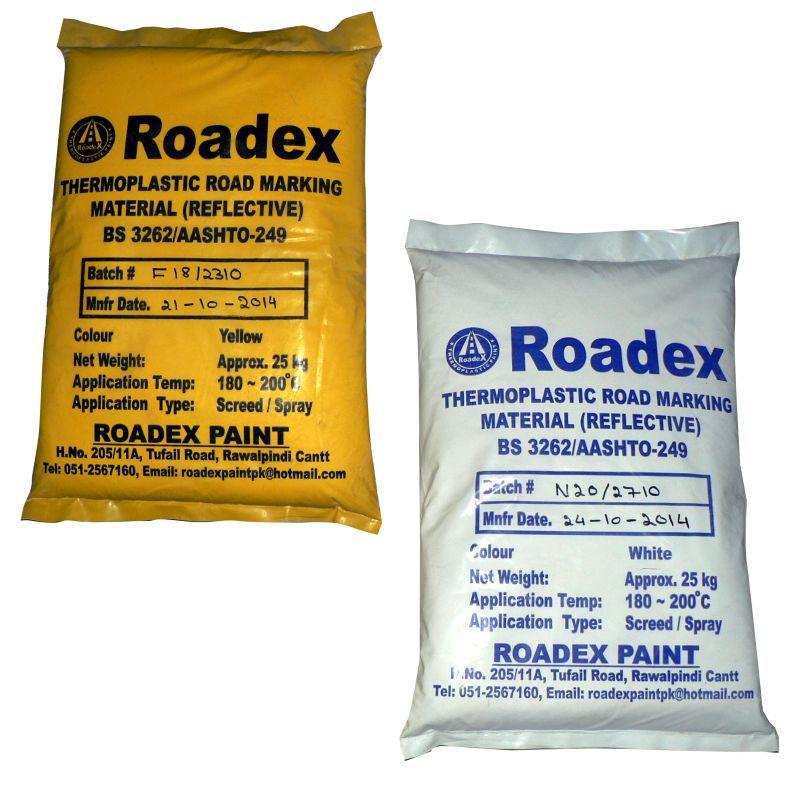

Road Thermoplastic Paint (TP Paint) is produced following BS 3262: Part 1/1989 and AASHTO 249 specifications.

| Color | White | Yellow |

| Density | 1.94 | 1.97 |

| Flash Point | >230°C | >230°C |

| Softening Point | >65°C | >65°C |

| Drying Time | 4 minutes at 30°C | 4 minutes at 30°C |

| Pigment Type | Titanium dioxide | Lead Chromate |

| Binder | 18-22% by weight | 18-22% by weight |

| Luminance Factor | More than 70% | More than 60% |

| Mixing Ratio | Not applicable | Not applicable |

| Coverage | 3.5 kg/sqm at 1.5 mm thickness | 3.5 kg/sqm at 1.5 mm thickness |

| Solvent Cleaner | Not applicable | Not applicable |

| Finish | Uniform | Uniform |

| Application | By Screed/Spray Machine | By Screed/Spray Machine |

| Glass Beads (Premix) | 20% by weight | 20% by weight |

| Packing | 25 kg | 25 kg |

Application of Thermoplastic Road Paints

- The asphalt surface must be dry and clear of debris, grease, and loose items.

- You can apply Roadex Thermoplastic paint using a screed at 190°C ten °C and a spray at 210°C 10°C. Manually applying special marking is an option.

- In a pre-heater, Roadex TP Paint is heated to 190°C 10°C (Boiler).

- To ensure that the material is fully melted and blended, we must add Roadex TP bags to the boiler one at a time. Before moving the material to the application machine, it is mixed for a short time at a temperature of 180°C 10°C to create a flowable viscosity.

- Apply 400–500 gm/sqm of glass beads to the freshly heated marking.

Packaging & Storing

HDPE 25-kilogram bags are an option for packaging. To achieve a minimum shelf life of twelve months, store it under a dry, shaded location.

Security and Precautions

When handling the material, keep your hands away from your skin, eyes, and mouth. To prevent burns, wear protective gear like gloves, masks, goggles, etc. Avoid smoking, flames, and sparks close to the kettle. Ecologically sound with No VOC.

Reviews

There are no reviews yet.