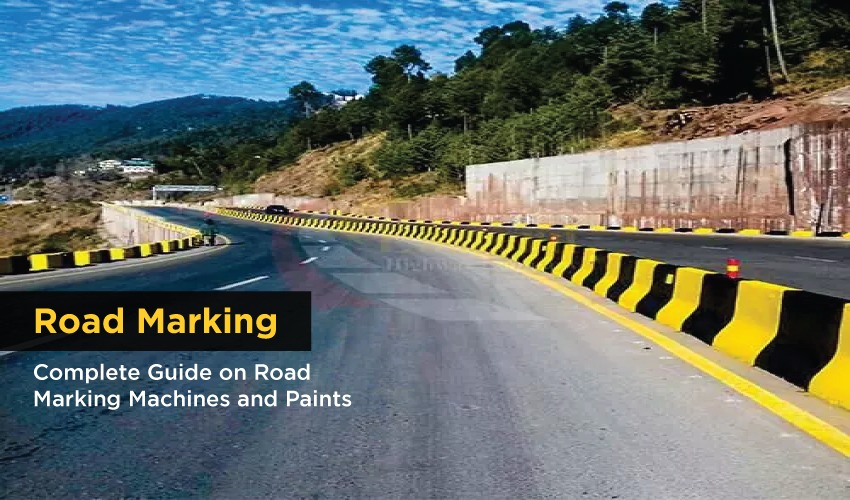

Road markings are actually an application of paints or materials on road surfaces. Road Markings help in guiding and controlling the traffic. They channel the tramper and cyclist’s movement into a safe position. Markings are there to guarantee a smooth and orderly flow of traffic and to promote road safety.

Safety Markings or drive signs can be defined as lines, patterns, or words that are marked on the pavement or road.

Different Types of Road Marking used on roads

Longitudinal markings

The main purpose of longitudinal marking is to guide and navigate the drivers for encouraging movements and to enjoin catching steering at certain dangerous locales to avoid sideswipe and head-on collision accidents. Eastern Highway has products like “Centreline Traffic lines, No passing zones, warning lines, edge lines”, that came in longitudinal road markings.

Transverse markings

Transverse markings are marked along the direction of traffic where immediate action is needed by the drivers. The transverse markings are handed across the expressway for traffic control with broken lines, single/ double nonstop lines similar to stop markings, and give-way markings. Eastern Highway has products like “Stop line marking, Pedestrian/Zebra crossing, Directional arrows for the road, that came in transverse road marking.

Hazard Marking

The hazard markings grease the major conduct of the vehicles similar to traffic coupling/ diverging, forbidding cross-over, and diverting the traffic ahead of dangerous situations. These markings are generally done with badge and slant marking, door marking, and prohibitory marking. The markings made on the road are in blocks similar to zebra crossing for pedestrians, and triangular and checkered markings for speed combers. The quality of block marking with acceptable visibility is of utmost significance.

Arrow Markings

The arrows painted on the expressway are meant to give directions for the drivers to take mandatorily turns. Arrow markings are painted on the roads or roads for furnishing the right direction to the drivers and they must take or follow these obligatory turns to avoid traffic confusion.

Block Marking

Block marking is marked in the form of blocks similar to zebra crossing for walkers and chequered blocks and triangular blocks for speed combers. The markings made on the road are in blocks similar to zebra crossing for pedestrians, and triangular and checkered markings for speed combers.

Facility marking

Directional markings are the markings that’s pronounced and painted in terms of words, so it’s easy to understand and allow the drivers to take action consequently. The characters of the communication are stretched so it’s visible to the drivers looking at a lower angle.

This marking helps to grease the parking of vehicles and gives the drivers an idea about parking space limits and restrictions. It also prevents encroachment of designated places like Bus stops, fire line Zones, etc. Eastern highway car parking marking came in this type of road marking.

Road Marking Machines & its Types

A road marking machine is a kind of device specially used to define different traffic lines on blacktop or concrete faces to offer guidance and information to drivers and pedestrians.

Regulation for parking and stopping can also be indicated by the traffic lanes. Line marking machines conduct their work through screeding, banishing, and scattering thermoplastic paint or cold solvent paint onto the paved road.

Grounded on the different driving modes road marking machines have their types. The types include

- Hand-drive type

- Tone-propelled type

- Driving-type

- Truck-mounted type

Grounded on the marking greasepaint applied on highway roads, all the road marking machines could fall into two major categories:

- Thermoplastic paint pavement marking machines

- Cold paint breathless pavement marking machines.

Thermoplastic Road Marking Machine

A hand-push road line marking machine is mainly used for the painting of road traffic safety signs, such as zebra crossings, pavements, lanes, and some other road signs. It is the key equipment for the construction of hot melt roads with signs lines, which usually work together with the hot melt kettle to finish the marking construction.

The machine is equipped with an automatic glass bead dispenser. An ideal thermoplastic road marking machine, this road marking machine gives the user great flexibility, which is very convenient for repainting highway roads.

Self-Propelled Thermoplastic Road Marking Machine

A self-propelled (automatic driving type) road line marking machine is mainly used to paint road traffic safety signs, such as zebra crossings, pavements, lanes, and other road signs.

It is the key equipment for the construction of hot melt road marking lines, which usually works together with the hot melt kettle to finish the marking construction. The machine is equipped with an automatic glass bead dispenser.

Thermoplastic Paint Remover Machine

Markings on the roads are designed for the long run, but sometimes they must be removed. For instance, when a traffic situation changes or an area is redesigned or the waste/broken marking lines are before marking new ones.

It efficiently scrapes off marking lines through the spinning cutting head at the bottom of the machine. The cutting head is replaceable.

Thermoplastic Paint Pre-Heater Double Tank

Thermoplastic Paint Pre-Heater also known as a Hot Melt Kettle, is one of the main pieces of equipment for the construction of a thermoplastic road marking line.

It involves melting, heating, and mixing the thermoplastic material making it ready for application via the road marking machine. They offer single-tank and double tank hydraulic and mechanical pre-heaters.

CR Road Marking Machine

Hand-push Cold Paint Road Marking Machine with High-Pressure Spray System. A hand-push road line marking machine that uses cold paint such as chlorinated rubber-based paint for marking.

Applications of cold paint marking are asphalt/concrete roads, parking lots, school area markings, and so on.

Hoffman H16 Thermoplastic Road Marking Machine

Two-in-one (TP and CR) Automatic Road line marking machine which is mainly used for the painting of road traffic safety signs, such as zebra crossings, pavements, lanes, and some other road signs.

Water-Based Road Marking Machine

Hand-push Cold Paint Road Marking Machine with an Airless Spray System. A hand-push road line marking machine that uses cold paint such as water-based/chlorinated rubber paint for marking.

Applications of water-based paint marking are asphalt/concrete roads, airport runways, parking lots, sports courts such as basketball courts, and so on.

Which Type of Paints is used for Road Marking?

Markings on the road (also called line marking or pavement marking) can be applied using colorful trappings and paints. These paints for drive signs are chosen reliant on the appearance and mark being made. These paints each have different properties, similar Anti-skid, reflectivity, life, and performance.

The materials most constantly used in road and highway road markings are:

- Thermoplastic

- Water-grounded paint

- MMA

- Epoxy resin-Epoxy paint for road marking

All this organic matter provides the paint with strong weather and wear resistance. TP paint provides excellent adhesion and its thicker film gives a longer life than any other road paint.

Types of Paints for Road Marking

Eastern Highway offers different types of road marking paints all over Pakistan & Internationally. Roadex is used by Eastern Highways in all of their products of the road with signs. The brand is known for being the best Road Marking Paint manufacturer and supplier. Eastern highways find them as a trusted partner as they provide Thermoplastic Paint (TP Paint). Their paints are of high-quality drive sign material grounded on hydrocarbon and natural resin.

- Thermoplastic Road Marking Paint

- CR Road Marking Paint

- Glass Beads

- Kerb Stone Paint

- Water-Based Paint For Runway

- TP Road Marking Paint

Benefits of Road Marking

Regulation Of Road with Signs

Traffic drivers who are on the road must adhere to driving and traffic regulations. Road markings support this by pressing driving forces that are allowed on specific parts or stretches of the road with signs.

These comprehensible road signs allow drivers to follow road regulations directly. Drivers who are aware of the difference between solid and broken white lines know when to stay in their lane or when it’s all right to catch another vehicle. They can make left or right-hand side turns safely.

They won’t get caught in the unheroic, X-marked, “Do Not Block” crossroad boxes when the light turns red, which can land the drivers heavy penalties and create frustrating fresh traffic.

Safety of Drivers and Pedestrians

Highway Road Markings increase safety both for drivers and walkers. Painted, largely visible walker lanes and crosswalks cover walkers using them correctly. Drivers on the other hand laggardly down and stop, allowing pedestrians to walk across safely.

Other driver’s and walkers’ safety drive signs include lading and Parking zones; easily designated parking areas, as well as no parking and hitch-down zones.

These types of roads with signs are important on roads, as well as in marketable areas, promenades, seminaries, and government structures.

Improvement of nighttime Visibility

Understandable driving signs can reduce the threat of night-related driving accidents. Drivers face all kinds of situations on the road, including heavy rain during typhoon season, or the appearance of fog in elevated locales. Roads with signs give added safety for long-haul truck drivers doing overnight drives.

It allows them to see lanes and corners more easily, especially on parochial roads with no stoplights. Drivers can calculate more unswervingly when to speed up or decelerate down safely along the trace.

Benefits to Senior Citizens and PWD

Drive signs on roads create much-demanded designated parking and access spaces for elderly citizens and persons with disabilities (PWDs).

Paths and supermarkets can lot and group designated parking spaces for elderly citizens and persons with disabilities closer to boardwalk entrances and driveways, as well as marking ramps and walker access areas for their convenience.

It’s important to designate parking and walkers access to all. This is a fair and practical way for public and private establishments to take care of this community.

Conclusion

Road Marking Machines provided by Eastern Highway is very easy to use and give a basic, natural plan, so the user doesn’t have to go through hours on upkeep, cleaning, or sorting out how your machine functions. We are leading road marking machine manufacturers as we provide the road marking machine to users who need fast, efficient marking immediately.

If a pinched citation for road marking machines and paints, a road marking machines and paints reasonable for your business, kindly get in touch with us right away. Our well-disposed and learned staff individuals offer specialized help 24 hours every day, seven days per week.

Frequently Asked Questions:

1. Which paint is used in road marking?

Thermoplastic paint or road marking paint is commonly used for road markings.

2. What is the name of the road marking machine?

Road marking machines are often called line marking machines or road stripers.

3. What are the tools used in road marking?

Tools include road marking machines, spray guns, stencils, rollers, and thermometers.

4. How does a road marking machine work?

To create lines and symbols, a road marking machine applies paint or thermoplastic material on the road surface using a spray system or heated extrusion.

5.What are the 4 types of road markings?

– Longitudinal markings

– Transverse markings

– Object markings

– Special markings

6. What is marking on road?

– Road marking refers to lines, patterns, or symbols painted on road surfaces to guide drivers and pedestrians.

7. What are the techniques of road marking?

– Spray application

– Thermoplastic marking

– Preformed tapes

– Cold plastic marking

8.What are the major road markings?

– Lane markings

– Pedestrian crossings

– Stop lines

– Arrows and symbols